What's the problem?

Pipework, pipelines, tanks & other metal structures.

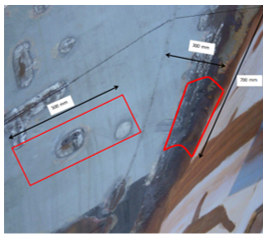

First of all, let’s look at the problems which metallic assets can experience. External and internal erosive forces and corrosive substances can lead to pitting and thin-wall defects. If not addressed soon enough, they are likely to go through-wall. We also see issues with localised damage on large structures, such as storage tanks and even boat hulls. Finally we will look at more innovative uses for non-metallic solutions, addressing the issues of pipe support erosion and corrosion.

What's the common repair options?

Some repair methods you may be familiar with:

Let’s look at some repair methods, such as cut and weld. Apart from all the typical metallurgical issues associated with hot work, there is of course downtime. We also know that welding requires a high level of expertise.

When methods alternative to welding are being used such as clamps, there is a question of longevity. Even when we accept the repair to be “temporary”, we want it to last close to the lifetime of the asset and not require ongoing maintenance.

What's the solution?

Composite Repair

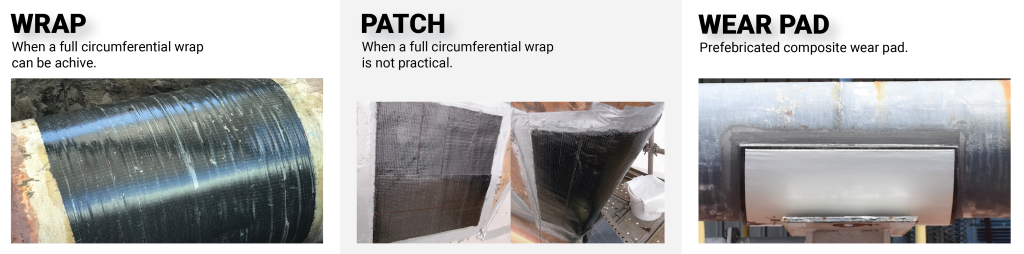

If this is a new topic for you, you might be asking what a composite repair is. Composite repairs are basically repair systems made up of a thermoset resin used in conjunction with glass or carbon fibre reinforcement. This reinforcement can be a mixture of the two materials or made of something else entirely. The advantages it offers are simple:

- No heat/hot work involved.

- No shutdown – these repairs can be completed online, provided that you can stop any leak.

- It is a cost-effective repair when compared with its counterparts.

Composite repairs can be defined by the following features: