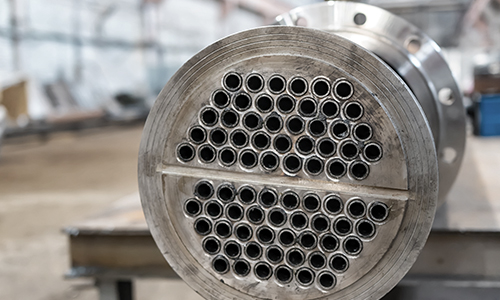

Belzona provides a variety of solvent free metal repair composites and epoxy coatings for repair and protection of critical pieces of equipment such as heat exchangers. Areas including tube sheets, water boxes, flange faces, division bars and end covers can be protected against galvanic corrosion as well as chemical attack. Our cold curing epoxy products allow for rapid, in-situ application minimising downtime whilst providing long-term erosion and corrosion protection. Belzona materials are excellent electrical insulators, which enables them to prevent galvanic corrosion by isolating the dissimilar metals used in heat exchangers.

Heat exchanger restoration

Heat exchangers can be repaired using cold applied metal repair composites and epoxy coatings that will not only rebuild heat exchangers’ components to their original profile, but will also:

- Provide long-term erosion and corrosion resistance

- Eliminate galvanic corrosion

- Prevent crevice corrosion

- Minimise equipment downtime

- Provide high temperature resistance

- Offer outstanding chemical resistance against a wide range of chemicals

- Eliminate the need for hot work

- Reduce expensive replacement costs

- Extend equipment life

Belzona metal repair materials give outstanding performance under many varied service conditions. Belzona 1111 (Super Metal) is frequently used for general repairs to heat exchangers’ components such as tube sheets, flange faces, water boxes and end covers. Areas subjected to high erosion and corrosion can be rebuilt using Belzona 1311 (Ceramic R-Metal) and large areas which require longer overcoating times can be restored using Belzona 1121 (Super XL-Metal). Additionally, we offer high temperature materials such as Belzona 1511 (Super HT-Metal) that can be used to rebuild heat exchangers operating at temperatures up to 150°C (302°F).

Heat exchanger protection with epoxy coatings

Our metal repair composites are designed to be coated with a wide range of Belzona epoxy coatings to achieve long-term erosion and corrosion protection of heat exchangers. Our range of coatings include Belzona 1321 (Ceramic S-Metal), specifically designed to provide erosion resistance in continuous immersion at temperatures up to 60°C (140°F) and Belzona 1341 (Supermetalglide), which is used when efficiency enhancement is required. Equipment operating at temperatures up to 130°C (266°F) can be coated with Belzona 1391T, and where ultra-high temperature resistance is required Belzona 1593 can withstand temperatures up to 160°C (320°F).

Other specialist coatings incorporating chemical, high temperature, erosion and cavitation resistance or a combination of these properties ensure Belzona has a solution for almost all service conditions.