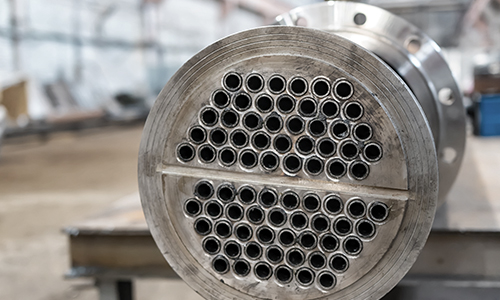

WCS provides a full range of VAM cold-curing repair composites and high-performance coating systems to rebuild and protect critical areas of heat exchangers—including tube sheets, water boxes, flange faces, division bars, and end covers. These solutions eliminate the need for hot work, reduce downtime, and deliver long-term corrosion and chemical resistance, even in demanding industrial environments.

Because VAM coatings are excellent electrical insulators, they also help prevent galvanic corrosion by isolating dissimilar metals commonly found in heat exchangers.

1 . Composite Rebuilding (VAM Paste Grade System – VAM M1 & VAM P1)

Heat exchanger components such as tube sheets, water boxes, flange faces, and end covers often suffer pitting, wall loss, galvanic corrosion, and chemical attack. The VAM Paste Grade System (VAM M1 and VAM P1) provides a cold-applied, high-strength rebuilding solution that restores damaged surfaces to their original profile. These materials adhere strongly to metal substrates and enable fast in-situ repair—reducing downtime and eliminating the need for hot work.

WCS repairs help to:

- Provide long-term erosion and corrosion resistance

- Eliminate galvanic corrosion on dissimilar metals

- Prevent crevice corrosion in tight or complex geometries

- Minimize equipment downtime with cold-curing application

- Deliver strong chemical and temperature resistance

- Avoid hot work entirely

- Reduce costly part replacements

- Extend overall equipment service life

2 . Heat Exchanger Protection with VAM C1

After rebuilding, VAM C1 delivers long-term protection against corrosion, chemical exposure, and temperature variations. Its excellent insulating properties help prevent galvanic corrosion between dissimilar metals inside heat exchangers. VAM C1 forms a seamless, durable barrier that enhances service life, minimizes future maintenance, and supports reliable operation under continuous immersion.

VAM C1 provides:

- Excellent erosion and corrosion resistance

- Chemical protection against a wide variety of process media

- Electrical insulation to prevent galvanic corrosion

- Strong adhesion to metallic substrates

- Long-term stability under elevated temperatures

- Resistance to cavitation and localized turbulence

Whether the heat exchanger handles seawater, chemicals, high-velocity fluids, or hot media, VAM C1 forms a durable, protective barrier that significantly extends operational life.